The plan is to check the gravity after 3 days and most likely add a 1/2 lb of sugar to each carboy to keep the yeast going. After another two days, do the same thing with the remaining pound. I've already set a fermentation schedule and the temp can be raised if needed. I also poured a satellite sample into a clean beer bottle which has been in one of the chambers at the same temperature. It's already reading 1.060 so the yeast are definitely doing their job.

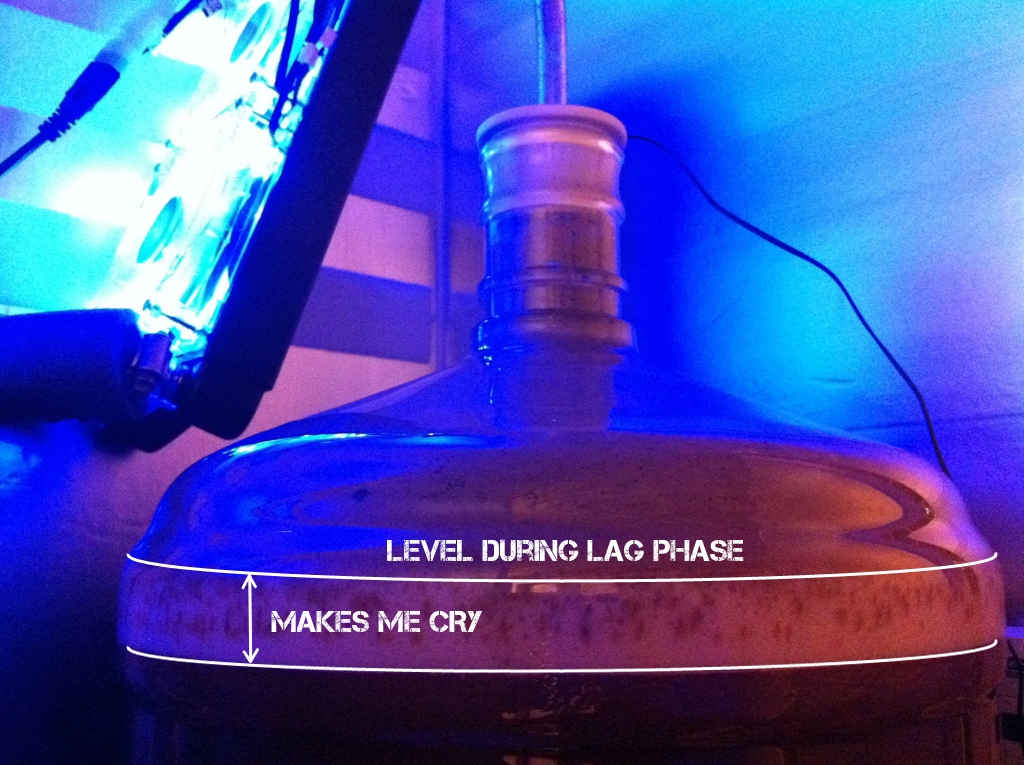

One thing I'm not thrilled with is how much beer I lost due to blowoff. This is not usually a problem with the temps kept in check, but with this much sugar and yeast, it's almost unavoidable. Unless of course I build a burton union system! (scoundrel has one and I need to ask him if it works well)

Carboy 1 | Carboy 2 |