|

Thanks Jerry, for making us smile by sending over this great cartoon! You can check out more of his work by visiting JerryKing.com

0 Comments

There are a few different ways to carbonate beer in a keg and a number of factors to consider. How quickly does it need to be carbonated? Is the beer warm or cold? Let's first decide how carbonated we want our beer, then we can choose the best way to set up the equipment. The amount of CO2 in beer is measured by volumes and can vary slightly depending on the style. Around 2.5 volumes is pretty typical for most styles in the United States. Here's a chart that correlates beer temperature and PSI to help us out. You can see by the graphic that setting the regulator to 10 PSI with the beer temperature at 38°F will put it at 2.38 volumes. The next term to understand is equilibrium (sorry for the geek speak). This represents the minimum amount of pressure that is needed to maintain the gas disolved in the beer. In our example above, it usually takes about a week until the beer has reached this point. If the beer is warm, it will take longer for the CO2 to disolve at the same PSI. With these things in mind, there are two typical ways that homebrewers carbonate using CO2. Slow "Forced" CarbonatingThe first method, sometimes called "set and forget it", basically means that gas is slowly injected at whatever temperature and PSI you have set. Once equilibrium is reached, no more gas can be absorbed unless the PSI is increased or the temperature changes. Here are a few common scenarios:

This last example is our preferred method of carbing. We use a small 5lb tank that easily fits in the keezer with the kegs. This is the fastest "non-shake" method of carbonating that we've found and it's nice because this extra time puts a little more age on the beer. Note that all connections must have tightened hose clamps or the tank will be empty in no time! Fast "Forced" CarbonatingAlthough a bit less predictable, the other way to carbonate with CO2 involves shaking the keg while gas enters the beer and there are two schools of thought on this. Some people shake with the gas line facing up (liquid side toward the floor) for fear of getting beer in the gas line. They typically set the regulator to 25-30 psi, connect the gas line to the cold keg, lay it flat to create the most surface area, then roll and shake the keg gently for about 20 minutes. Allow the keg to sit for a while and bleed off most of the gas before doing a test pour. Repeat if necessary. Others find that setting the PSI to 40-50 prevents any backflow and the beer is shaken with the gas line at the bottom. This method has the benefit of listening for bubbles as CO2 enters the beer. The idea is to lower the pressure by 2-5 PSI each time the bubbles stop, then continue rocking the keg so the bubbles start again as the gas present goes into solution. Once the PSI on the regulator is around 20, the target pressure desired should be pretty close and near a good level of carbonation for serving. I'm over carbonated... what happened??!!Both of these methods can lead to over carbonation and the beer must be tasted periodically to insure this doesn't happen. If it does, the solution is simple but can take time to solve.

Disconnect the gas and pull the pressure release value until the hissing stops. CO2 will come out of solution to re-pressurize the head space and be removed from the beer. Do this again every few hours until the desired volume is reached.  I submitted one beer to the National Homebrew Competition this year and it was an American Barleywine called "Hard Target". We've posted a few things about this beer in the past and if you missed it, the recipe and fermentation notes will bring you up to speed. One of the more interesting things about this beer was recorded in our "Add Oak And Bourbon To Keg" article where it was warm aged on oak and bourbon for almost a year. I was happy to find that the nylon bag held up quite well during this time. There was no deterioration at all and the stainless steel link chain was perfectly clean after running under water. The oak chips also showed very little wear. I'm extremely pleased with how this beer turned out and can't wait to see the NHC judging notes. I'll be sure to post up the score sheets when they come back (good or bad!). Eiswine say what??On a side note, I fermented this beer in two 5 gallon carboys and they finished a bit differently. One of the carboys (the one I submitted) attenuated a little more and has a smoother, dry character. The second fermenter produced a sweeter version and, although some people would prefer it for the style, we ultimately decided that smoother was better.

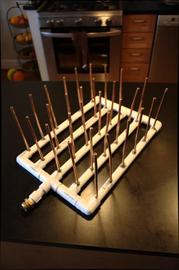

Why did I mention this? Well, I have 4 gallons left of the slightly-sweet barleywine that may be a great candidate for a freezing process that concentrates alcohol and flavor. This process is typically used to create the strongest member of the bock family called an "Eisbock". Eisbock, which is German for "icebock", is made by freezing the beer into a slushy consistancy, effectively removing water from the beer. As it concentrates, the bitterness, final gravity and color are all boosted. I'm freezing a test sample soon, just to be sure it works for this beer. I'll try to post a write-up of the sample tasting and definitely the full process if we do it. p.s. My buddy Scoundrel submitted 3 beers this year and I certainly wish him luck and hope his beers find the second round! Gooooo BREWGEEKS! Cheers! TK  When I first laid eyes on MalFet's bottle washer I thought, what is this fascinating invention he created? Is it some kind of medieval torture device.. or perhaps the latest and greatest NYPD road spike strip? Oooh, how about a blow dart machine gun? Bigfoot's hairbrush??! Umm, No. It's actually a very cleverly conceived bottle washer that hooks up to a submersible pump and sits over the sink or wash basin. Here are a few details as described by MalFet along with a video and link to the parts list and full article. Any questions about it can be asked via the "Original Link" at the end of the post. "It's a very simple concept, but it can wash, rinse, and sanitize 30 bottles with virtually no effort. I built a frame out of 1/2" cpvc fit to a standard rectangular milk crate, used 1/4" copper refrigerator coil for the vertical bottle spouts, and push water through it with a 1/4 HP submersible pump. The pump sits in my sink filled with whatever I want to wash with (pbw->rinse water->star san), and the milk crate rests right on top of it. I made three of them since I always bottle two ~4.5 gallon batches at a time, and washing those 90 bottles is now trivial. I fill the sink with PBW, let it run on each crate for 5-10 minutes, drain the sink, fill the sink with star-san, and then run it again for a minute or two. My active time for 90 bottles is probably somewhere in the neighborhood of 5 minutes. It's so painfully easy that I kind of hate myself for only doing this now after all these years. I get plenty of power from this pump, and without the bottles to block it the stream of water coming out extends 3-4 feet above the spouts. I ran through a batch of very grimy, dried out bottles and they came out completely clean after 15min of PBW. If I built it again, I might actually use copper for the frame and sweat it all together. The JB Weld holds reasonably well, but in knocking the washer around a bit a few have come loose. They still work perfectly fine even when loose, but welded metal would obviously be more durable over the long run." [Read More]  HA-PPY BIRTH-DAY BREWGEEKS! You are one year old! Well, it's a little late... but as they say, just because I missed your birthday doesn't mean that you don't look like a monkey. Alright, maybe nobody says that. O.o I hope you have enjoyed reading BrewGeeks over the past year and, although there isn't much about our equipment and process that we haven't written about, we will continue to bring you DIY articles and beer information in the future. Articles could come slowly from time to time but such is life and the challenge of balancing work and play. Cheers! |

Thanks for visiting BrewGeeks! Popular ArticlesHave Feedback or Suggestions?

Contact Us Archives

January 2022

Categories[ Powered by Yeast ]

|

| BrewGeeks | Sniffing Airlocks since 2010 |